Acrylic sheets

Model No.︰-

Brand Name︰Yiplastic

Country of Origin︰China

Unit Price︰US $ 80 / Square

Minimum Order︰1 Square

Product Description

Introduction for acrylic sheets profile:

CAST ACRYLIC SHEET

Cast acrylic, is manufactured by a process whereby MMA(Methy! Methacrylate monomer) liquid is pumped into a mould made from two sheets of glass. The mould/monomer is then submerged in warm water and the process of polymerization takes place. Features:

Casting is more labor intensive, making it more expensive. Casting yields a harder, sturdier, and more homogenous product. Casting lends greater chemical resistance over extrusion, making it the preferred material for uses involving fragrance, lotions, or other solvents.Available in a broad range of standard and custom colors for a variety of applications, cast acrylic is more pliable than extruded, less likely to bend,chip,or melt during milling.

e original glass and approximately 200 times stronger. They have many uses and they are a growing industry.

Old and typical building materials are being replaced by polycarbonate sheets for more weight lifting strength, energy saving, high durability and easy application.

They can be used as partitions, in greenhouses, in the interior and exterior of buildings and many more.

EXTRUDEDACRYLIC SHEET:

Extrusion is a continuous manufacturing production method where acrylic monomers are first heated then fed through barrels where the chemical process occurs. As a result,extruded acrylic is heterogeneous with properties that may vary depending upon the direction of extrusion.

All product range

| yiplastic product range | ||

| Product Type | Thickness | Width |

| 1) twin-walls polycarbonate sheet | 4-12mm | 2100mm |

| 2) triple-walls polycarbonate sheet | 8-16mm | 2100mm |

| 3) four-walls polycarbonate sheet | 8-20mm | 2100mm |

| 4) honeycomb polycarbonate sheet | 6-11mm | 2100mm |

| 5) 5 layer honeycomb polycarbonate sheet | 14-25mm | 2100mm |

| 6) X-structure polycarbonate sheet | 14-40mm | 2100mm 1570 mm |

| 7) solid polycarbonate sheet | 0.7-8mm | 1220mm/1560mm/1820mm/2100mm |

| (Usually 1220*2440mm, 2050*3000mm) | ||

| 8) corrugated polycarbonate sheet | 0.7-2.5mm | Customized |

| 9) locking-design polycarbonate sheet | 3-10mm | 1040mm |

| 10) Polycarbonate sheets accessories | Aluminum and PC for option | |

| B. Length | ||

| No limit(Recommend 5800, 6000, 11800, 12000mm to suit 20'container &40'container). | ||

| C. Color | ||

| Clear/Transparent, Lake Blue, Green, Blue, Opal, White, Brown/Bronze,Silvery Gray, Red, Yellow, etc. | ||

Features:

Extruded acrylic costs less than cast and is more dimensionally stable, meaning the thickness is more consistent across sheets. Softer, with a lower melting temperature than in its cast form, extruded acrylic is easier to laser cut, rout, and polishes more cost-effectively.Extruded acrylic is less susceptible to dirt,lint, or particulate contamination in the production process.Additionally,because of its lower melting point,it is better suited to cementing and thermoforming.

Company strength :

1)4 factories with 19 production lines;(Imported line and demostic line)

2)Flexible products line to meet different marketing location .

3) Timely delivery and strong packing

4) Experienced International team from Raw materials to Finished products .

5) Production Capacity: 12000 tons/year;

6) 100% virgin raw materials of BAYER , LOTTER ,LG,Rohm and etc;

7) Faster delivery order and free sample to support.

8)we are a mufacturering vendor with verical set-up ,which means we have a great control of supply chain and we are cost -effective

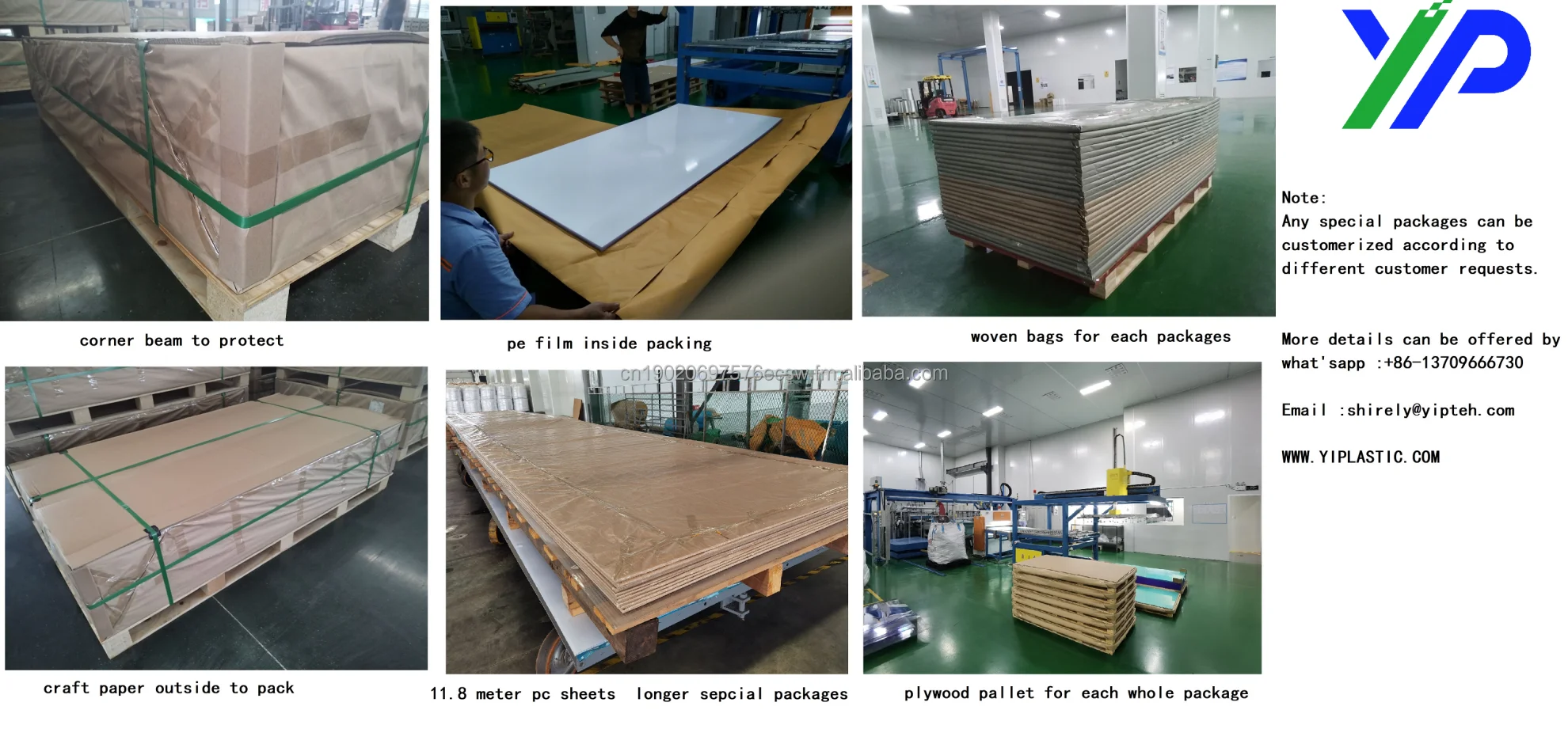

PACKING &Shipping way

PROFESSIONAL PACKING WAY FOR EVERY ORDER EXPORT

CONTACTS US

Shirely xu

OveseaManager

Whats'app&wechat &line &viber : +86-13709666730

Email: Shirely(2)yipteh.com

Webiste :www.yiplastic.com

What'app & Wechat

Payment Terms︰ TT/LC/Western Union

Product Image