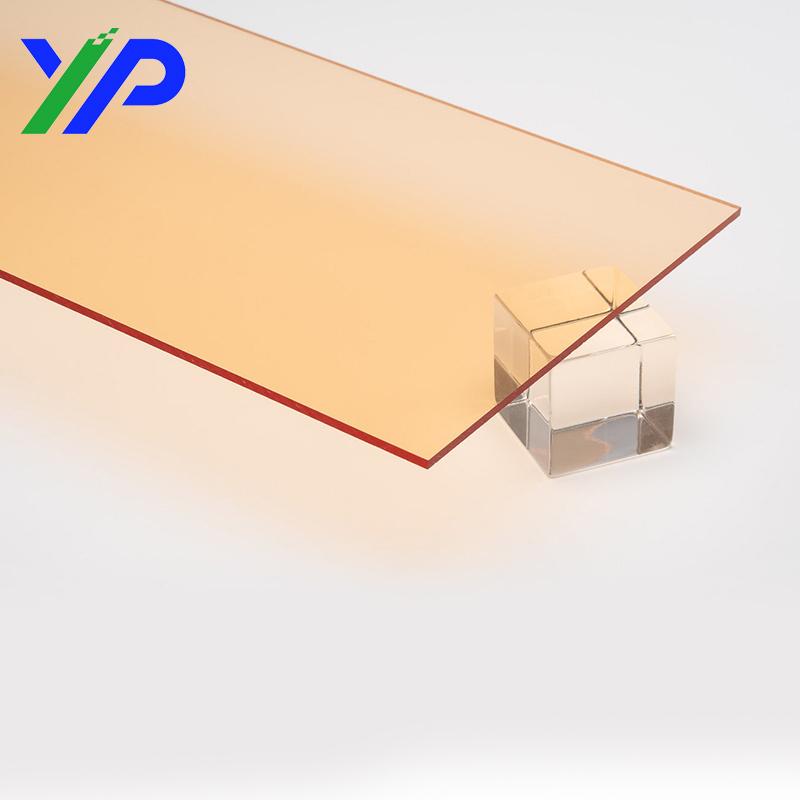

Polycarbonate Solid Sheets

Model No.︰-

Brand Name︰Yiplastic

Country of Origin︰China

Unit Price︰US $ 80 / Square

Minimum Order︰1 Square

Product Description

Introduction for polycarbonate U profile:

High impact strength, often used for security protection

High light transmission, about the same as glass

Sound insulation, better than the same thickness of glass

Rich colors, can be customized for customers

Can be developed into a variety of additional functions

Easy processing :Polycarbonate panels can be cut directly with a common saw, drilled with a common drill bit, and cold bent,Cold bending, punching and thermoforming are possible for solid sheets up to 6 mm in thickness

•Simply installed

•Light weight

•Avoid alot and sound insulation

•Light weight and high wind resistance

•Impact resistance

•Temperature range:-40~+120°C

Advantages:

It is stronger than aluminum and has less weight than it. It is the best to use for varnishing and glazing.

Good workability and plasticity.

According to the actual needs of the site,it can bend intoarched and semi-circular patterns.

Excellent lighting effect

Permeable amorphous point

Its transparency is almost the same as that of glass,as it transmittance can reach 90%

Specifications:

| Thickness | weight | Light transmittance % | Shock strength | Sound isolation | Width | Length | Color |

| (mm)2 | (g/m2)2.4 | (Astm d1003)88 | j/m (Astm d256)

900 |

(db)

22 |

(mm) | (mm) |

Clear Opal Bule Green Bronze |

| 3 | 3.6 | 87 | 930 | 24 |

1210 1560 1810 2100 |

3000 | |

| 4.5 | 5.4 | 86 | 1100 | 27 | |||

| 6 | 7.2 | 85 | 1300 | 28 | |||

| 8 | 9.6 | 84 | 1400 | 30 | |||

| 10 | 12 | 82 | 1500 | 32 | |||

| 12 | 14.4 | 81 | 1600 | 34 | |||

| 15 | 18 | 36 | |||||

| 18 | 21.6 | 37 | |||||

| 20 | 24 | 37 |

Physical properties:

| PHYSICAL PROPERTIES | TEST METHOD | UNITS | VALUE |

| PROPERTY | ASTM D792 | g/cm² | 1.2 |

| PHYSICAL | ASTM D1003 | % | 45-92 |

| Specific Gravity | ASTM D570 | % | 0.35 |

| Light Transmission | ASTM D882 | Mpa | ≥60 |

| Water Absorption Equilibrium,24HRS | ASTM D882 | % | ≥90 |

| MECHANICAL | ASTM D1525 | ° c | 135 |

| Tensile Strength | ASTM D1204 | % | ≤l |

| Elongation Ultimate | ASTMD 149 | KV/MM | ≥30 |

| THERMAL | ASTMD 257 | Ω-cm | >1X10' |

| Vicar Softening Temperature | ASTMD257 | Q | >1X10' |

| Strain relief-135°C | Class | HB |

Applications:

1. Vehicles

2. Exhibition layouts

3. High voltage switch cabinet panel

4. LED panel boards

5. Highway road noise barriers

6. Buildings and sheds

7. Greenhouses

8. Security

9. Instruments

10. Fences

FREQUENTLY ASKED QUESTIONS

1. Is every anti-fog sheet anti-scratch too?

Yes, they are specially coated with anti-scratch and anti-fog layers.

2. Does the anti-fog layer increases the weight and make sit heavy to easily use?

No, the anti-fog layer is a very delicate layer that helps your sheets be fog-free. It does not affect the quality and weight of the sheets.

3. Is the anti-fog coating permanent or temporary

No. the anti-fog coating layers are not permanent.

4. Can I have the sheet in my customized length and width?

Yes, we make sheets in customized dimensions per order.

5. Can I get the anti-fog coating on my other sheets from you?

Yes, we can also coat your other sheets no matter flat or multilayer with your desired anti-fog and anti-scratch coating.

6. How thick is the UV coating layer?

UV Coating Layer is 50µm in thickness.

7. What is the standard size of sheets?

The Standard Size is 0.5 14mm (customizable).

8. Are they humidity-free too?

Yes, they are humidity-free too along with anti-fog.

CONTACTS US

Shirely xu

OveseaManager

Whats'app&wechat &line &viber : +86-13709666730

Email: Shirely(2)yipteh.com

Webiste :www.yiplastic.com

What'app & Wechat

Payment Terms︰ TT/LC/Western Union

Product Image